DiskFlashback

Rob Smith has brought us all an amazing new Windows package! If you are a retro computer user weather it be Amiga, Atari ST or PC, this is for YOU! See below for all the information and where to get it from his official page below.

(Taken directly from Robs page. For more information please visit his site directly)

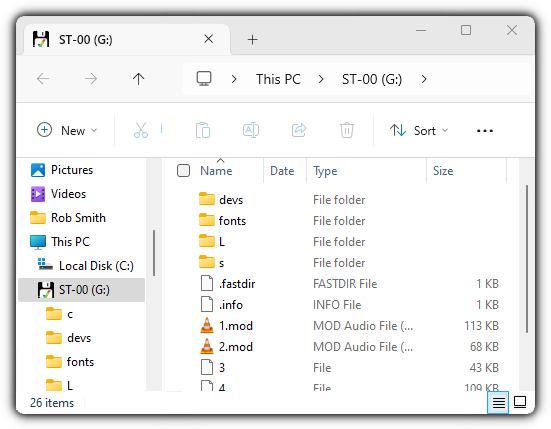

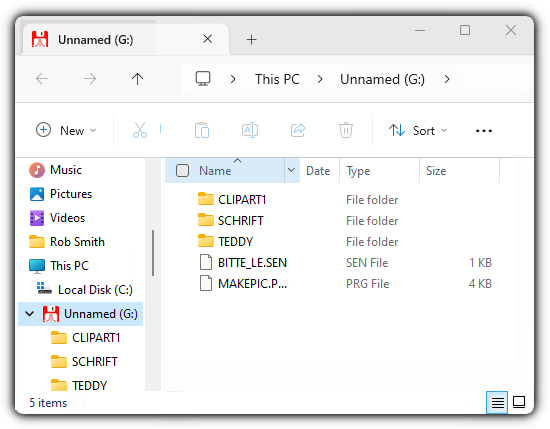

A Windows package to use Floppy Disk Images Files & Non-PC Real Floppy Disks in Windows, directly.

Why?

Most of the USB floppy drives are terrible. And modifying a drive for DrawBridge removes the IBM/PC floppy disk support in Windows. Plus I was getting annoyed having to boot WinUAE just to copy a file to an ADF (or disk).

So I decided to build this – And all the silly playground arguments from childhood now behind us I gave a little love to the Atari ST too (untested, I don’t have one!)…

I’d been planning on building this since 2017, and now, with a simple double-click I can now access the contents of these disk image files directly!

See the Getting Started Guide! for more details!

Features

- Mount ADF, DMS*, IMG, IMA, ST, MSA*, HDA, HDF and SCP* files as virtual drives (* read only)

- Supports AmigaDOS OFS/FFS DD & HD Disks

- Supports IBM/PC FAT12/16 DD 720k & HD 1.44Mb Disks

- Supports Atari ST FAT12/16 GemDOS Single and Double Sided normal & extended Disks

- Supports Dual Format Amiga/Atari floppy disks and mounts them as two drives! (read only)

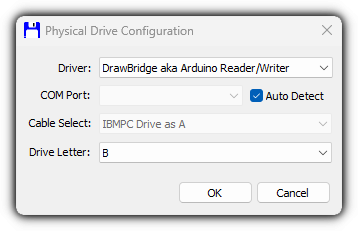

- Use DrawBridge, Greaseweazle or SupercardPro as a real windows drive letter

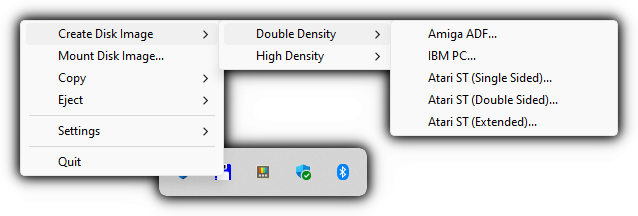

- Create blank disk images for the above formats.

- Rip real floppy disks to file

- Write disk images to real floppy disks

- Install boot blocks on Amiga disks

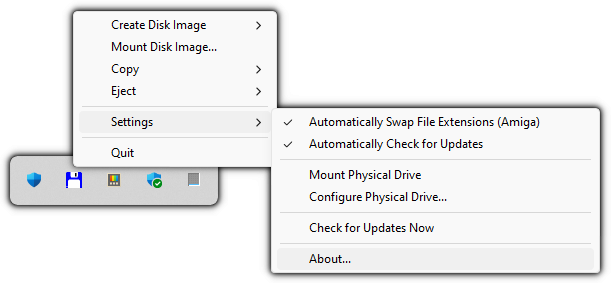

- Optionally silently swap file extensions (eg: mod.thismusic to thismusic.mod)

Download – It’s Free!

Consider sending me a tip to say thanks!

WINDOWS MAY DETECT THIS AS A VIRUS

THIS IS A FALSE POSITIVE AND YOU ARE SAFE TO IGNORE IT

Download DiskFlashback V1.0.0.6 beta

System Requirements:

Windows 10/11 64-Bit Only

How does it work?

DiskFlashback is powered by:

- Dokany for the Virtual Drives

- ADFLib for the Amiga File System

- FatFS for the FAT12/16 File System

- xDMS for DMS File Support

- FloppyBridge for Real Floppy Disk Support

DiskFlashback is OpenSource and available under the GPL2 Licence, and available from GitHub.

Join me on Discord for discussion about the product!